Fiber coating UV LED for Fiber drawing coloring high speed and high

quality

Print quality benefits:

Less dot gain;UV inks&LED inks cure instantly exposed to

ultraviolet light. This keeps the ink on top of the substrates with

less dot gain, resulting in crisper imagery and more vibrant

consistent colors

More flexibility:

Instant curing also allows design flexibility for printing on a

wider variety of papers, plastics, and foils. The ultra-violet

printing process also enables visual effects and tactile textures

to be applied to the press, saving time and money

Fiber coating curing is a highly skilled process. In the fiber

drawing tower, it is produced at a speed of 2km per minute. The UV

curing process determines the quality of the fiber. Traditional

curing methods consume a lot of electricity, generate a lot of

heat, and have high maintenance costs. UV LED technology makes up

for the traditional UV-cured shortboard, which is a new,

energy-saving and efficient technology.

For every 1 centimeter of fiber produced, the LED UV lamp and the

extraction system use approximately 0.5-0.7 degrees of power. We

produced about 240 million core kilometers of fiber in 2018 in

China, and the total power consumption will exceed 160 million kWh.

Compare with conventional UV lamp

1. For every 1 centimeter of fiber produced, the LED UV lamp and

the extraction system use approximately 0.5-0.7 degrees of power.

2. We produced about 240 million core kilometers of fiber in 2018

in China, and the total power consumption will exceed 160 million

kWh.

3. UV-LEDs are five times more efficient than mercury lamps.

4. If UVLED is applied for optical fiber production in 2018, it can

save RMB256 million(It's the visible cost).

5. Invisible cost : Extracting the heat generated by the drawing

tower area and maintaining the constant temperature of the

cleanroom( 23-26°C & 50% RH); the high curing efficiency of UVLED

peak intensity can increase the drawing capacity; but the heat

generated by mercury lamp will cool the exhaust system, and the

cost of consumables in the mercury lamp use process;

Technical advantages of UV-LED:

UV-LEDs are five times more efficient than mercury lamps.

If UVLED is applied for optical fiber production in 2018, it can

save RMB256 million. (It's the visible cost)

Invisible cost : Extracting the heat generated by the drawing tower

area and maintaining the constant temperature of the cleanroom(

23-26°C & 50% RH);the high curing efficiency of UVLED peak

intensity can increase the drawing capacity, but the heat generated

by mercury lamp will cool the exhaust system, and the cost of

consumables in the mercury lamp use process;

UV LED Optical Fiber Curing Light Parameter:

Specification | Valid emitting area(mm ) | Illuminate distance(mm ) | Wavelength(nm ) | Luminous intensity(mW/cm2 ) |

uniformity

|

Luminous half Angle

|

Cooling method |

UVLED Spot Light Source | >φ10 | 350 | 365 | >400 | >90% | 1.7° | Nature convection |

| UVLED Area Light Source | 280x190 | 350 | >480 | >80% | 1.7° | Water cooling |

Technical advantages of UV-LED

► Intelligent design, self-test, abnormal alarm function.

High-temperature warning, real-time monitoring of light intensity,

automatic adjustment.

► Drive independent research and development design, currently used

in large quantities, stable and reliable performance;

► Precision optical design for optimal illumination output;

► Precision heat dissipation design ensures optimal heat

dissipation of LED modules;

► In India, Thailand, Singapore and the European Union, we have a

24-hour after-sales service team.

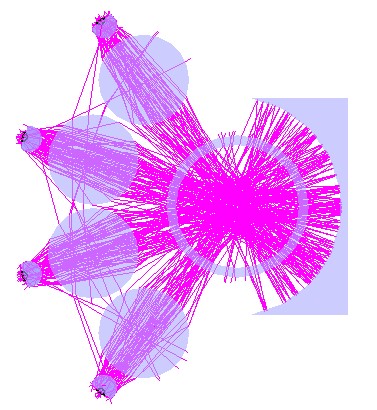

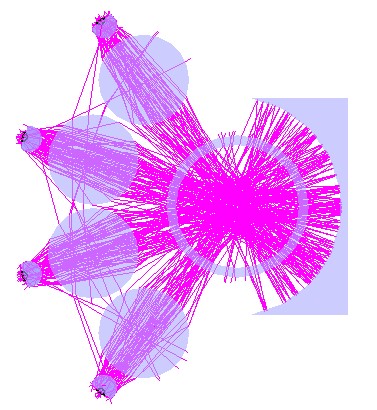

Optical modeling simulation

Application: Curved phone cover exposure